Laser Direct Writing (LDW ) uses laser beam to create a controlled localized damage on the surface. The pattern is drawn in CAD program, which then is etched on the surface of material by a laser spot. In a typical setting, the laser spot is fixed, while the sample is moved under the beam. To prevent overwriting, the beam is switched off with shutters. Baltfab also uses galvanometric scanners, where laser beam is directed with a moving mirror. This typically provides higher writing speeds (up to 20 m/s). All laser systems in Baltfab have dedicated laser stages, but we are also flexible to rearrange existing setups if needed.

Currently, we operate 8 laser writing systems – CO2 industrial CW laser, five different nanosecond lasers, two picosecond lasers and one femtosecond pulse laser. Typically, the shorter the pulse, the less material is removed from the surface: fs laser removes about ~2-3 nm/pulse, ps ~100 nm/pulse, ns – ~1000 nm/pulse.

We use LDW for thin-film structuring, selective and localized modifications of surface.

Tested materials:

Ablation: glass, plastics, metals, semiconductors. Generation of Au colloidal nanoparticles in water, Si wafer cleaving. 3D writing in glass, polymers.

Our examples:

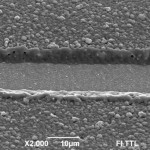

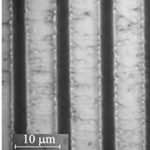

- ps laser: isolation trench in CIGS solar cel

- ps laser: isolation trench in CIGS solar cel

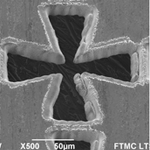

- ns laser: Cr trenches on glass